2025-11-07 Polyurethane rigid foam waterproof and thermal insulation integrated panels combine waterproof and thermal insulation functions and are widely used in building exterior walls, roofs and other scenarios. In order to extend its service life and maintain performance, scientific maintenance must be carried out in terms of daily cleaning, protection, inspection, repair, storage and transportation. The following are specific maintenance methods: 1. Daily cleaning and maintenance Clean the surface regularly and use a soft brush or vacuum cleaner to remove dust and debris on the board to avoid scratches with hard objects that may cause coating damage. For oil stains and stains, you can use neutral detergent (such as dishwashing liquid) mixed with warm water, wipe with a soft cloth and rinse with water. Do not use strong acids, alkalis or organic solvents (such as gasoline, Tianna water). To avoid long-term water accumulation, check whether the drainage system (such as roof gutters and exterior wall drains) is smooth to prevent accumulation of rainwater from causing soaking of boards and affecting the performance of the waterproof layer. 2. Protective measures to prevent ultraviolet aging. For boards that have been exposed to the sun for a long time, it is recommended to apply a layer of ultraviolet protective agent (such as polyurethane special paint) every 3-5 years.

Read More

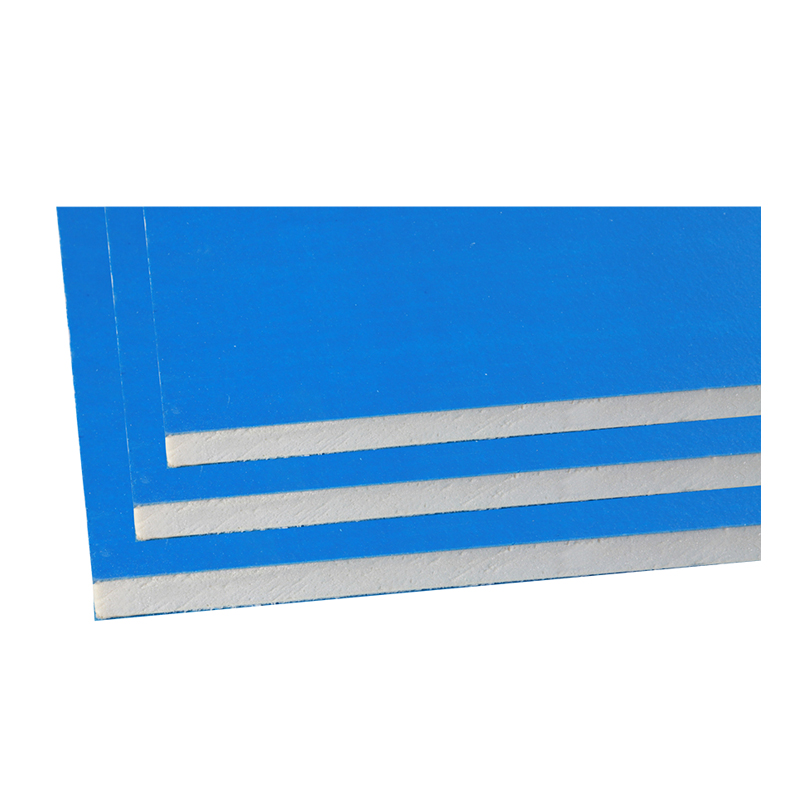

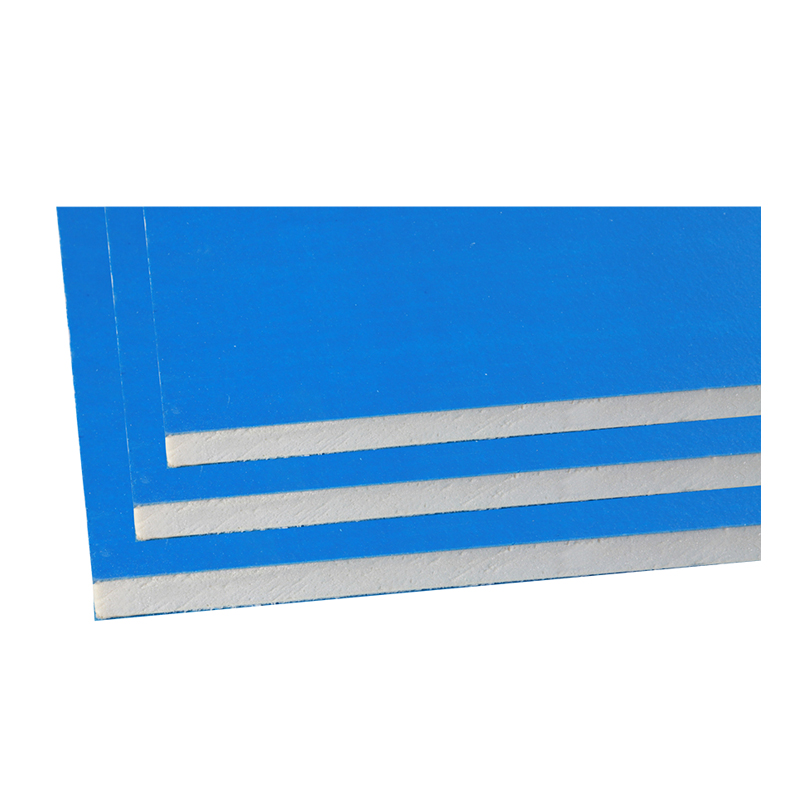

2025-11-05 The polyurethane rigid foam thermal insulation decorative integrated board combines the functions of insulation and decoration. It has significant advantages such as low thermal conductivity, waterproof and moisture-proof, fire retardant, long service life, efficient construction, strong decoration, environmental protection and energy saving. The details are as follows: low thermal conductivity, excellent thermal insulation performance. The thermal conductivity of polyurethane rigid foam is only 0.018-0.024W/(m·K). It is one of the smallest thermal conductivity coefficients among industrial insulation materials, much lower than EPS foamed polystyrene board. Its closed cell rate is as high as over 95%, which can effectively prevent heat transfer. Under the same thermal insulation requirements, it can reduce the thickness of the building's outer envelope, thereby increasing the indoor use area. Polyurethane rigid foam with outstanding waterproof and moisture-proof performance is a hydrophobic material with a closed cell rate of more than 90%. It will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water. This feature allows it to maintain stable thermal insulation performance in humid environments, especially in areas with rainy or high humidity. Fireproof

Read More

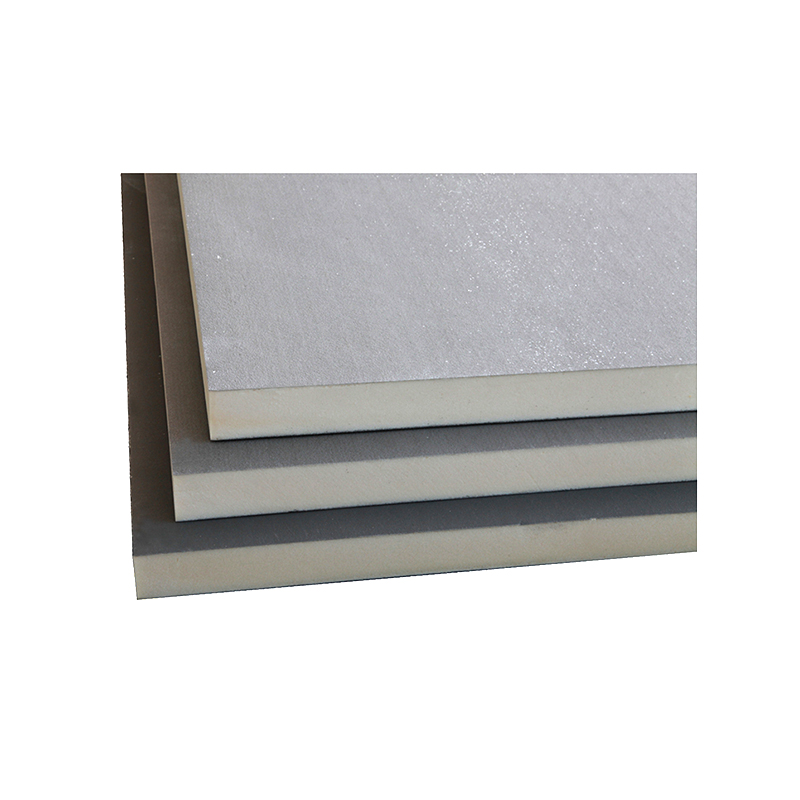

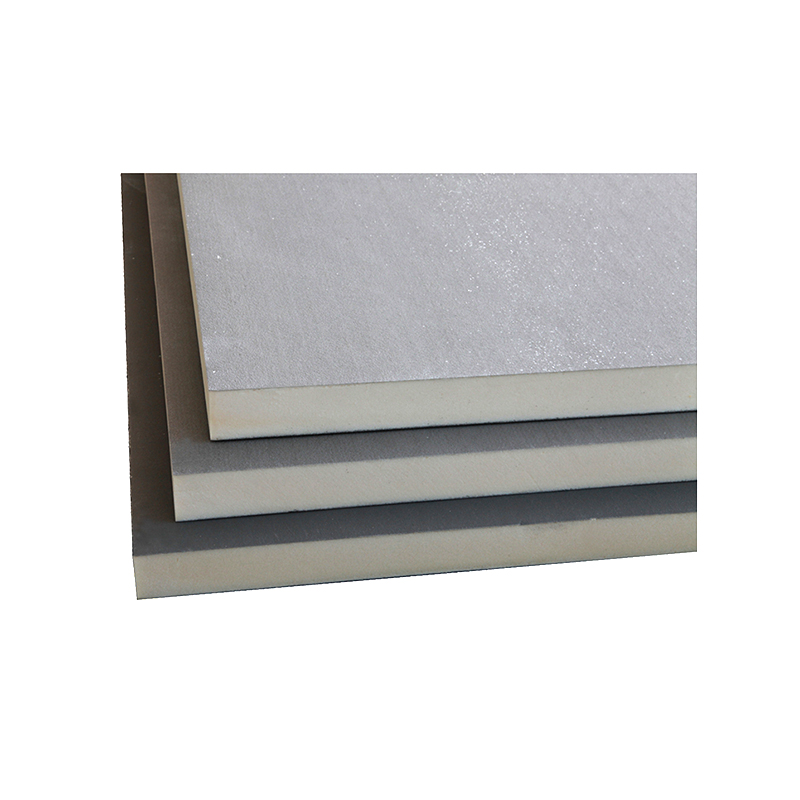

2025-11-03 SPD water-based foamed polyurea sound insulation insulation board is a composite material that combines all-water foamed polyurea foam and fiberglass mortar cloth reinforcement system. Its core advantages are reflected in five aspects: efficient sound insulation, stable thermal insulation, strong durability, wide adaptability, and green environmental protection. The specific analysis is as follows: 1. High-efficiency sound insulation performance This material uses all-water foamed polyurea foam as the core, and effectively blocks sound wave transmission through its closed-cell structure. In floor sound insulation scenarios, it can significantly reduce the transmission of noises such as footsteps and equipment vibration, meeting the new national standard's high requirements for residential floor sound insulation performance. For example, in the renovation of rough houses, after using this material, the floor impact sound level can be reduced to ≤65dB, reaching the 'good house' construction standard. 2. Stable thermal insulation effect and low thermal conductivity: The thermal conductivity of polyurea foam is low. Combined with the reinforcement effect of fiberglass mortar cloth, it forms a stable thermal insulation layer and reduces heat transfer. In the refined floor heating system, this material can maintain indoor temperature stability and reduce energy consumption.

Read More

2025-10-28 The usage method (installation method) of the Q-type rock wool thermal insulation and decorative integrated board is as follows: Base layer treatment: Ensure that the base wall is dry, clean, and free of floating dust, oil stains and other attachments that hinder bonding. The base plastering layer should meet the intermediate plastering standard, without blistering or sanding. The surface flatness should be measured with a 2-meter ruler, and the exposed joint gap should not be greater than 5mm. The yin and yang angles should be vertical and square, the straightness should be measured with a 2-meter ruler, and the gap between exposed seams should not be greater than 5mm. Pop-up line division: According to the design drawings and actual site conditions, pop-up vertical and horizontal control lines serve as the construction baseline. Determine the grid positioning lines to ensure that the board layout is economical, beautiful and safe. Plate cutting: Cut the plates according to the layout design of the building facade integrated plate to reduce waste. When cutting the integrated board, the required length should be cut strictly according to the length direction of the integrated board, and the required width should be cut according to the width direction of the integrated board. Prepare special binder: Pour clean water into a clean bucket and use electric stirring

Read More

2025-10-25 Polyurethane rigid foam insulation composite panel is a high-performance insulation material with polyurethane rigid foam as the core layer and composite metal or non-metallic surface materials on both sides. It is widely used in construction, industry, cold chain and other fields. Its functions can be summarized as the following core aspects: 1. Excellent thermal insulation performance and low thermal conductivity. The thermal conductivity of polyurethane rigid foam is only 0.018-0.024W/(m·K), which is much lower than traditional insulation materials (such as rock wool 0.035-0.045W/(m·K), EPS foam 0.038W/(m·K)). This means that at the same thickness, polyurethane rigid foam composite panels can more effectively prevent heat transfer and reduce energy consumption. Application scenarios: building exterior wall insulation, cold storage insulation, industrial pipeline insulation, etc. For example, in severe cold areas, building exterior walls using polyurethane rigid foam composite panels can reduce heating energy consumption by 30%-50%. Advantages of closed cell structure Polyurethane rigid foam is composed of more than 90% closed cells.

Read More

2025-10-22 The construction method of polyurethane rigid foam insulation decorative integrated board mainly includes the following steps and key points: 1. Prepare the base layer for inspection and treatment before construction: the base layer of the wall should be solid and flat, without delamination, hollowing, or cracking. Remove dust, dirt, oil stains and other impurities on the surface of the base layer. Conduct quality inspection on base walls to ensure compliance with construction requirements. Measurement and setting out: According to the design drawings and actual site conditions, pop up the dividing lines, door and window opening control lines and floor horizontal lines. Hang vertical reference lines at the large corners of the exterior walls to ensure construction accuracy. Material preparation: Prepare polyurethane rigid foam insulation decorative integrated panels, bonding mortar, mechanical fixings, caulking materials and other materials required for construction. Check the quality certification documents of the materials to ensure that the materials meet the design requirements and relevant standards. Preparation of construction machinery and tools: Prepare hanging baskets, scaffolding and other construction equipment to ensure construction safety. Prepare bonding mortar mixer, electric drill, screwdriver and other construction tools. 2. Construction steps: Preparing bonding mortar

Read More

2025-10-18 Polyurethane rigid foam waterproof and thermal insulation integrated panels require maintenance. Although they have excellent waterproofing, insulation and durability properties, during long-term use, performance may still be degraded or damaged due to environmental factors, construction defects or external forces. The following is a detailed description from three aspects: the necessity of maintenance, maintenance content and maintenance cycle: 1. The necessity of maintenance to extend the service life. Although polyurethane rigid foam materials are resistant to aging, if exposed to ultraviolet rays, temperature changes or chemical corrosion environments for a long time, surface powdering, cracking or insulation performance degradation may occur. Regular maintenance can slow down the aging rate and extend the service life of the board. Maintain waterproof performance. If the waterproof layer is damaged due to construction defects (such as improper joint treatment) or external damage (such as mechanical impact), it will cause water seepage problems and affect the safety of the building structure. Maintenance can detect and repair leaks in time. Ensure the insulation effect. If the joints of the panels are cracked due to loose installation, thermal expansion and contraction, or the surface is contaminated (

Read More

2025-10-16 Rock wool insulation integrated board is an exterior wall insulation material composed of rock wool and decorative panels. It has the functions of heat preservation, heat insulation, fire prevention, noise reduction and other functions. The following is the construction process of rock wool insulation integrated board for your reference.

Read More

2025-10-10 SPD water-based foamed polyurea sound insulation insulation board uses all-water foamed polyurea foam as the core material, combined with the composite fiberglass mortar cloth to strengthen the structure, forming a multi-functional building material with sound insulation, thermal insulation, waterproof and weather resistance properties. Its characteristics can be summarized in the following aspects: 1. Core material advantages All-water foamed polyurea foam is environmentally friendly: water is used as the foaming agent to avoid environmental pollution from traditional chemical foaming agents and complies with green building standards. Lightweight and high strength: Polyurea foam has low density but high compressive strength, which can effectively reduce building loads while maintaining structural stability. Closed cell structure: The foam has a closed cell structure inside, with low thermal conductivity and excellent thermal insulation performance, which can effectively prevent heat transfer. Composite fiberglass mortar cloth enhances structural stability: Fiberglass mortar cloth serves as a reinforcing layer to improve the tensile strength and impact resistance of the board and prevent cracking or deformation. Durability: Fiberglass material is corrosion-resistant and aging-resistant, extending the service life of the board and reducing subsequent maintenance costs. 2. Performance characteristics

Read More

2025-10-07 The construction process of hard foam polyurethane composite board mainly includes steps such as base processing, measurement and layout, material preparation, installation of keels (with keel system), pasting composite boards, anchoring and fixing, plate joint treatment, finishing layer construction, etc. The following is a detailed introduction: Prepare weather conditions before construction: Pay attention to weather forecasts, avoid construction in severe weather such as strong winds, rain and snow, and ensure construction safety and project quality. Personnel and materials: Ensure that the construction staff is complete and prepare all the boards, spare parts and other materials required for construction, such as bonded mortar, anchors, sealants, alkali-resistant glass silk fiber grid cloth, etc. Construction tools: Prepare special equipment and equipment such as micro-polyurethane hard foaming pouring machines, air compressors, hanging baskets or scaffolding, and conduct on-site operation inspections. Only after passing the qualification can it be put into use. Base layer treatment: After the exterior wall of a newly built building has passed the concealed project acceptance, a leveling layer may not be used, but the masonry should be grouted. For concrete walls and masonry walls, the base surface should be

Read More