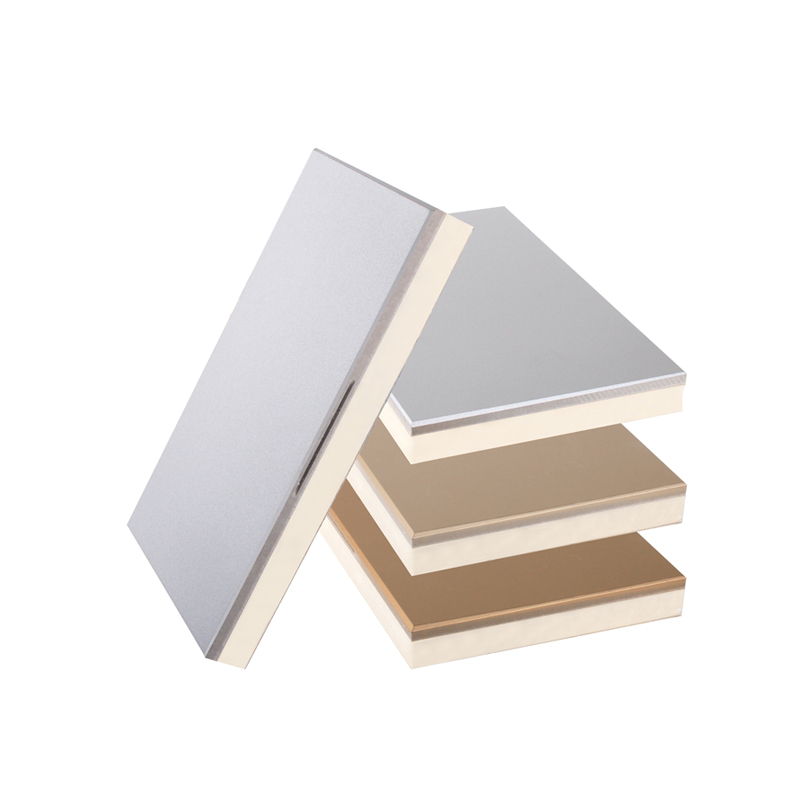

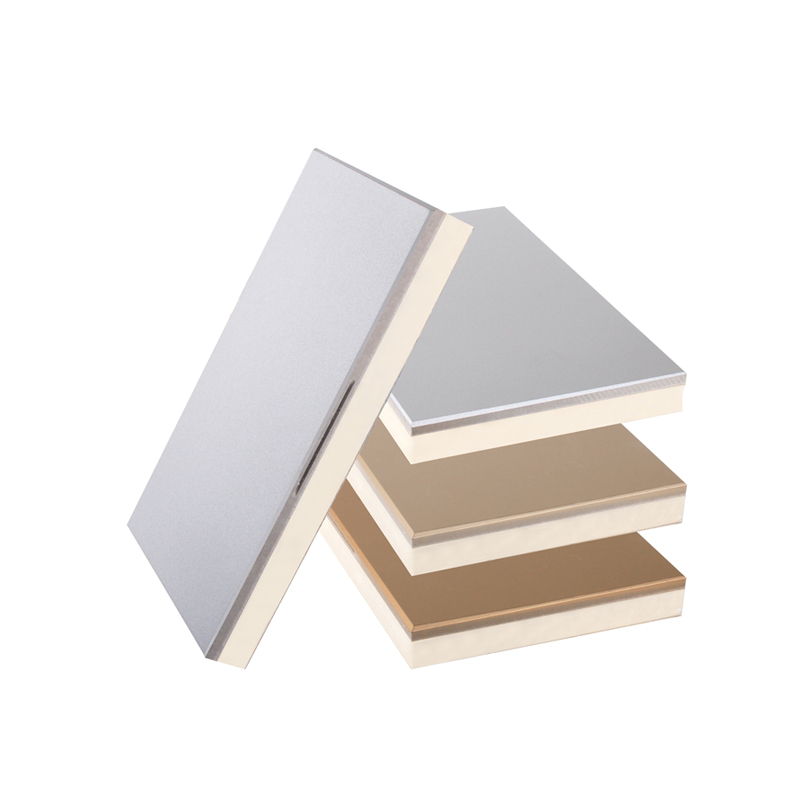

2025-08-05 Polyurethane hard bubble waterproof and insulation integrated board ('polyurethane integrated board') is a new type of building board that integrates waterproof, insulation, heat insulation, lightweight, high strength and other functions. It uses polyurethane hard bubble as the core material and combines the waterproof layer (such as aluminum foil, polymer film or asphalt-based material) with the insulation layer through special processes. Its application range is wide, covering multiple fields such as building exterior walls, roofs, cold chain logistics, industrial equipment, etc. The following are the specific application scenarios and advantages analysis: 1. Building exterior wall insulation system 1. Residential and commercial building exterior wall application scenarios: Integrated exterior wall insulation and decoration projects of high-rise residential buildings, office buildings, shopping centers and other buildings. Advantages: High efficiency insulation: Polyurethane hard bubbles have low thermal conductivity (≤0.024W/(m·K)), which can significantly reduce building energy consumption and meet energy-saving standards (such as China's 'Public Building Energy-Saving Design Standards' GB 50189). Waterproof and moisture-proof: outer waterproof film (such as aluminum foil

Read More

2025-07-30 Polyurethane hard foam insulation composite board (PU hard foam composite board) is a high-efficiency insulation material with polyurethane hard foam as the core material and composite metal or non-metallic surface materials on both sides (such as color steel plates, aluminum foil, cement fiberboard, etc.), which is widely used in exterior walls, roofs, cold storages, pipelines and other scenarios. The usage method needs to be combined with design specifications, construction technology and safety requirements. The following is a detailed description of the four stages: selection preparation, construction process, key node control, acceptance and maintenance: 1. Selection and preliminary preparation 1. Selection and pre-preparation 1. Selection and building exterior walls according to the scene: Metal-surface polyurethane composite panels (such as color steel sandwich panels) are preferred, with a thickness of the surface material ≥0.5mm, core material density ≥35kg/m³, and a fire resistance level of B1 (flammable retardant) or A (not combustible, flame retardant is required). Cold storage insulation: double-sided stainless steel or aluminum foil composite panel, core density ≥40kg/m³, closed porosity ≥95%, and low temperature environment (-40℃ to +80

Read More

2025-06-17 In the early stages of its establishment, the company was committed to the development and application of new building waterproof coatings.Since 2006, it has entered the building energy-saving insulation industry and started researching and developing polyurethane rigid foam exterior wall (roof) ins

Read More

2025-06-17 In the early stages of its establishment, the company was committed to the development and application of new building waterproof coatings.Since 2006, it has entered the building energy-saving insulation industry and started researching and developing polyurethane rigid foam exterior wall (roof) ins

Read More

2025-06-17 In the early stages of its establishment, the company was committed to the development and application of new building waterproof coatings.Since 2006, it has entered the building energy-saving insulation industry and started researching and developing polyurethane rigid foam exterior wall (roof) ins

Read More