2026-01-28 On January 27, 2026, the fourth council and commendation meeting of the fifth session of the Shaoxing Exploration and Design Industry Association concluded successfully at the Shaoxing International Hotel. This meeting mainly includes the summary of the association's work in 2025, the association's work ideas in 2026, the display of outstanding works in the 'Good House' design competition, and the commendation of the annual advanced ones. Zhejiang Keda New Building Materials Co., Ltd. was awarded the title of 'Advanced Member Unit'. At the meeting, Director Chen of the Shaoxing Municipal Housing and Urban-Rural Development Bureau made an important speech, requiring the association’s work to be integrated with the policies and spirit of central documents, encouraging the association to break through, innovate, and try, and create a fair competition environment for the industry. At the same time, Director Chen fully affirmed Zhejiang Keda New Building Materials Co., Ltd.'s exterior wall insulation, floor and floor sound insulation and waterproof series products, and highly praised Keda's spirit of continuous innovation and keeping up with the development pace of 'good houses'. Mr. Tian Junxian, general manager of Keda Company, wrote 'SPD Water-based

Read More

2026-01-15 Supported by Zhejiang Building Waterproofing Industry Association, Zhejiang New Wall Materials Industry Association, Water Supply and Drainage Professional Committee of Hangzhou Civil Engineering and Architecture Society, Zhejiang Building Materials Industry Association, sponsored by Chief Engineer's Home (CEA), Chief Engineer's Home (Zhejiang) ) Operation Center hosted the '2026 Green Building Chief Engineer (CTO) Summit Forum/The 12th CTO Home (Zhejiang) Academic Annual Conference', which was grandly held on the afternoon of January 10, 2026 at Hangzhou Haihaihai International Hotel. With the theme of 'Technological Innovation, Craftsmanship, Green Empowerment, and Collaborative Construction', this conference brought together more than a hundred project directors, chief engineers, procurement and cost directors, technical experts and industry leaders from real estate development, architectural design, construction, material research and development, technology companies and university scientific research institutions across the country to conduct in-depth discussions around core topics such as green building policy trends, technological innovation, and engineering practice.

Read More

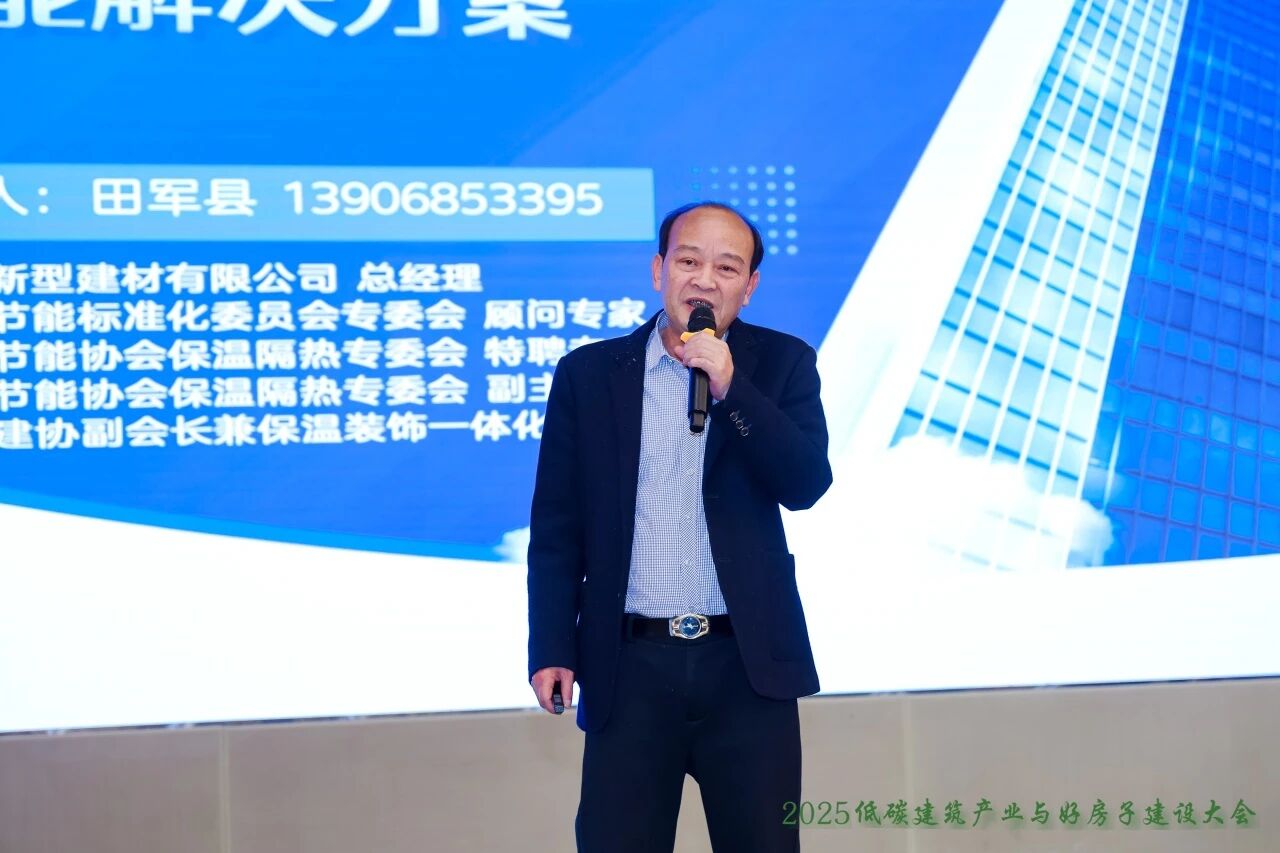

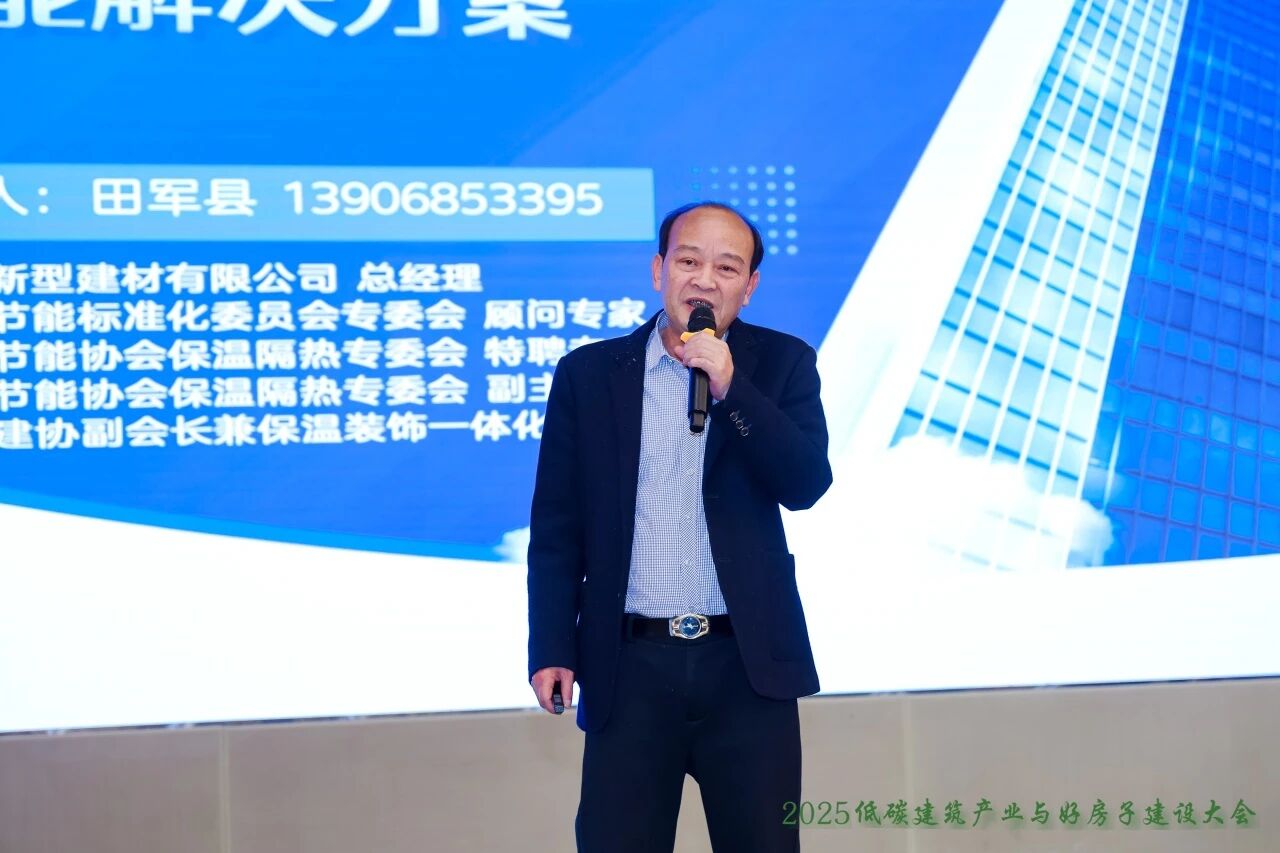

2025-12-18 As the '15th Five-Year Plan' is about to begin, the low-carbon construction industry and 'good house' construction conference under the background of 2025 urban renewal was successfully held in Chuzhou, Anhui. With the theme of 'Technology Empowering a Zero-Carbon Future,' this conference brings together elites from all walks of life in government, industry, academia, and research to discuss how to promote the green transformation of the construction industry through technological innovation and industrial collaboration under the guidance of the 'dual carbon' goal, and build safe, comfortable, green, and smart 'good houses' for the people. The conference was guided by the China Building Materials Industry Economics Research Association and co-sponsored by the Low-Carbon Building Branch of the China Building Materials Industry Economics Research Association, the Construction and Engineering Disaster Prevention and Mitigation Branch of the China Disaster Prevention Association, the Zhongguancun Aosen Park Green Building Innovation Technology Alliance, the Anhui Urban Science Research Promotion Association, and the Anhui Artificial Environment and Low-Carbon Energy Society. It is organized by the Green and Low-Carbon Construction Branch of the China Building Energy Conservation Association, the Comfortable Housing Working Committee of the China Building Energy Conservation Association, and the Henan Provincial City Council.

Read More

2025-11-08 On November 8, a delegation from Jiangsu Haodong Group visited our company to conduct learning and exchanges around SPD water-based foamed polyurea sound insulation panels and floor sound insulation and insulation systems.

Read More

2025-11-07 Polyurethane rigid foam waterproof and thermal insulation integrated panels combine waterproof and thermal insulation functions and are widely used in building exterior walls, roofs and other scenarios. In order to extend its service life and maintain performance, scientific maintenance must be carried out in terms of daily cleaning, protection, inspection, repair, storage and transportation. The following are specific maintenance methods: 1. Daily cleaning and maintenance Clean the surface regularly and use a soft brush or vacuum cleaner to remove dust and debris on the board to avoid scratches with hard objects that may cause coating damage. For oil stains and stains, you can use neutral detergent (such as dishwashing liquid) mixed with warm water, wipe with a soft cloth and rinse with water. Do not use strong acids, alkalis or organic solvents (such as gasoline, Tianna water). To avoid long-term water accumulation, check whether the drainage system (such as roof gutters and exterior wall drains) is smooth to prevent accumulation of rainwater from causing soaking of boards and affecting the performance of the waterproof layer. 2. Protective measures to prevent ultraviolet aging. For boards that have been exposed to the sun for a long time, it is recommended to apply a layer of ultraviolet protective agent (such as polyurethane special paint) every 3-5 years.

Read More

2025-11-05 The polyurethane rigid foam thermal insulation decorative integrated board combines the functions of insulation and decoration. It has significant advantages such as low thermal conductivity, waterproof and moisture-proof, fire retardant, long service life, efficient construction, strong decoration, environmental protection and energy saving. The details are as follows: low thermal conductivity, excellent thermal insulation performance. The thermal conductivity of polyurethane rigid foam is only 0.018-0.024W/(m·K). It is one of the smallest thermal conductivity coefficients among industrial insulation materials, much lower than EPS foamed polystyrene board. Its closed cell rate is as high as over 95%, which can effectively prevent heat transfer. Under the same thermal insulation requirements, it can reduce the thickness of the building's outer envelope, thereby increasing the indoor use area. Polyurethane rigid foam with outstanding waterproof and moisture-proof performance is a hydrophobic material with a closed cell rate of more than 90%. It will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water. This feature allows it to maintain stable thermal insulation performance in humid environments, especially in areas with rainy or high humidity. Fireproof

Read More

2025-11-03 SPD water-based foamed polyurea sound insulation insulation board is a composite material that combines all-water foamed polyurea foam and fiberglass mortar cloth reinforcement system. Its core advantages are reflected in five aspects: efficient sound insulation, stable thermal insulation, strong durability, wide adaptability, and green environmental protection. The specific analysis is as follows: 1. High-efficiency sound insulation performance This material uses all-water foamed polyurea foam as the core, and effectively blocks sound wave transmission through its closed-cell structure. In floor sound insulation scenarios, it can significantly reduce the transmission of noises such as footsteps and equipment vibration, meeting the new national standard's high requirements for residential floor sound insulation performance. For example, in the renovation of rough houses, after using this material, the floor impact sound level can be reduced to ≤65dB, reaching the 'good house' construction standard. 2. Stable thermal insulation effect and low thermal conductivity: The thermal conductivity of polyurea foam is low. Combined with the reinforcement effect of fiberglass mortar cloth, it forms a stable thermal insulation layer and reduces heat transfer. In the refined floor heating system, this material can maintain indoor temperature stability and reduce energy consumption.

Read More

2025-10-31 On October 30, 2025, the 7th China Building Thermal Insulation Conference concluded successfully in Tianjin. As a leading company in the field of domestic building thermal insulation, Zhejiang Keda New Building Materials Co., Ltd. was invited to participate in the conference to discuss with industry experts and business representatives accelerating the improvement of exterior wall insulation (insulation and decoration integration) engineering technology, solving quality and safety risks, and empowering 'urban renewal'. Zhejiang Keda New Building Materials Co., Ltd. has been deeply involved in the field of polyurethane insulation composite panels for more than 20 years and is the creator of this technology in China. Its self-developed B1 flame-retardant core layer preparation technology achieves dual optimization of the flame-retardant and thermal insulation properties of the core material through its exclusive formula and process, effectively solving the pain points of traditional thermal insulation materials being flammable and lacking in durability. At present, Keda has established an industrial production capacity of 25,000 square meters of composite panels per day, and plans to further expand production to an annual output of 20 million square meters.

Read More

2025-10-28 The usage method (installation method) of the Q-type rock wool thermal insulation and decorative integrated board is as follows: Base layer treatment: Ensure that the base wall is dry, clean, and free of floating dust, oil stains and other attachments that hinder bonding. The base plastering layer should meet the intermediate plastering standard, without blistering or sanding. The surface flatness should be measured with a 2-meter ruler, and the exposed joint gap should not be greater than 5mm. The yin and yang angles should be vertical and square, the straightness should be measured with a 2-meter ruler, and the gap between exposed seams should not be greater than 5mm. Pop-up line division: According to the design drawings and actual site conditions, pop-up vertical and horizontal control lines serve as the construction baseline. Determine the grid positioning lines to ensure that the board layout is economical, beautiful and safe. Plate cutting: Cut the plates according to the layout design of the building facade integrated plate to reduce waste. When cutting the integrated board, the required length should be cut strictly according to the length direction of the integrated board, and the required width should be cut according to the width direction of the integrated board. Prepare special binder: Pour clean water into a clean bucket and use electric stirring

Read More

2025-10-25 Polyurethane rigid foam insulation composite panel is a high-performance insulation material with polyurethane rigid foam as the core layer and composite metal or non-metallic surface materials on both sides. It is widely used in construction, industry, cold chain and other fields. Its functions can be summarized as the following core aspects: 1. Excellent thermal insulation performance and low thermal conductivity. The thermal conductivity of polyurethane rigid foam is only 0.018-0.024W/(m·K), which is much lower than traditional insulation materials (such as rock wool 0.035-0.045W/(m·K), EPS foam 0.038W/(m·K)). This means that at the same thickness, polyurethane rigid foam composite panels can more effectively prevent heat transfer and reduce energy consumption. Application scenarios: building exterior wall insulation, cold storage insulation, industrial pipeline insulation, etc. For example, in severe cold areas, building exterior walls using polyurethane rigid foam composite panels can reduce heating energy consumption by 30%-50%. Advantages of closed cell structure Polyurethane rigid foam is composed of more than 90% closed cells.

Read More