2025-09-18 Polyurethane hard bubble insulation composite panel is a high-performance building enclosure material with polyurethane hard bubble as the core insulation layer and composite metal or non-metal panels on both sides. Its characteristics and advantages can be summarized into the following aspects: 1. Excellent thermal insulation performance Low thermal conductivity The thermal conductivity of polyurethane hard bubbles is only 0.018-0.024 W/(m·K), far lower than traditional insulation materials (such as 0.038 W/(m·K) of EPS and 0.035 W/(m·K) of rock wool). This means that at the same thickness, polyurethane hard foam composite panels provide more efficient insulation and reduce building energy consumption. The closed cell ratio of polyurethane hard bubbles in closed cell structure is as high as more than 95%, forming a continuous thermal insulation layer, effectively blocking thermal convection and thermal radiation. Even in humid environments, the closed-cell structure can prevent moisture penetration, avoid the increase in thermal conductivity due to water absorption, and ensure stable long-term insulation performance. 2. High strength and lightweight compression and impact resistance

Read More

2025-09-15 The role of the integrated polyurethane hard bubble insulation decorative board is mainly reflected in the following aspects: Excellent thermal insulation performance: The thermal conductivity of polyurethane hard bubbles is extremely low, only 0.018-0.024W/(m·K), and is one of the lowest thermal conductivity among all thermal insulation materials at present. This means that the required insulation layer thickness is thinner when the same insulation effect is achieved, thereby reducing the thickness of the building's outer enclosure structure and increasing the indoor use area. At the same time, its closed porosity is as high as more than 90%, and it is a hydrophobic material. It will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water, further ensuring the stability of thermal insulation performance. Excellent fire resistance: After adding flame retardant, polyurethane has become a flame-retardant self-extinguishing material. Its fire resistance reaches the B1 standard and can even meet the A-level fire resistance requirements through technical improvements. During combustion, carbon deposits will be formed on the surface of the polyurethane, effectively preventing the flame from spreading, and no occurrence of the high temperature

Read More

2025-09-12 The polyurethane hard bubble waterproof and insulation integrated board has the characteristics of high efficiency waterproof and insulation, fire safety, lightweight and high strength, durability and stability, environmental protection and energy-saving, convenient construction, and strong adaptability. The specific analysis is as follows: High efficiency waterproof and insulation: The closed cell rate of polyurethane hard bubbles is as high as more than 95%, and the water absorption rate is extremely low (≤1%), forming a dense and impermeable layer, effectively preventing moisture penetration. At the same time, its thermal conductivity is as low as 0.018-0.024W/(m·K), which is 1/2 to 1/3 of traditional insulation materials, which can significantly reduce the thickness of the building's outer enclosure structure and increase the indoor use area. Excellent fire safety performance: Polyurethane hard bubbles have become flame retardant and self-extinguishing materials after adding flame retardant. The softening point reaches more than 250℃. They do not flow or drip at high temperatures. When burning, carbon deposits form on the surface to effectively isolate the flame spread and produce no harmful gases. They comply with the national A-level fire protection standards. Lightweight, high strength and durability: the plate is light in weight, 40mm thick plate per

Read More

2025-09-10 The SPD water-based foamed polyurea sound insulation insulation board takes full water foam polyurea foam as the core. The system stability is enhanced through composite fiberglass mortar cloth, and is suitable for scenes such as rough houses and finely decorated floor heating. The usage method can be summarized into the following key steps: 1. Prepare the base layer before construction: ensure that the base layer is flat, dry, and free of cracks and depressions. If there are defects, it needs to be repaired and leveled in advance. Clean up dust, oil and other impurities on the surface of the base layer to ensure the bonding effect. Material inspection: Check whether the size and specifications of the insulation board meet the design requirements. The diagonal error should be less than 3mm and the allowable dimension deviation is ±2mm. Confirm that the auxiliary materials such as waterproof tape, vertical sound insulation sheet, wire mesh, etc. are of qualified quality and are not damaged. Environmental requirements: The construction ambient temperature should not be lower than 5℃ to ensure stable material performance. Avoid construction in severe weather such as rainy days and strong winds to prevent moisture from invading and affecting the bonding effect. 2. Positioning of the insulation board installation line: According to the design requirements, at the base layer

Read More

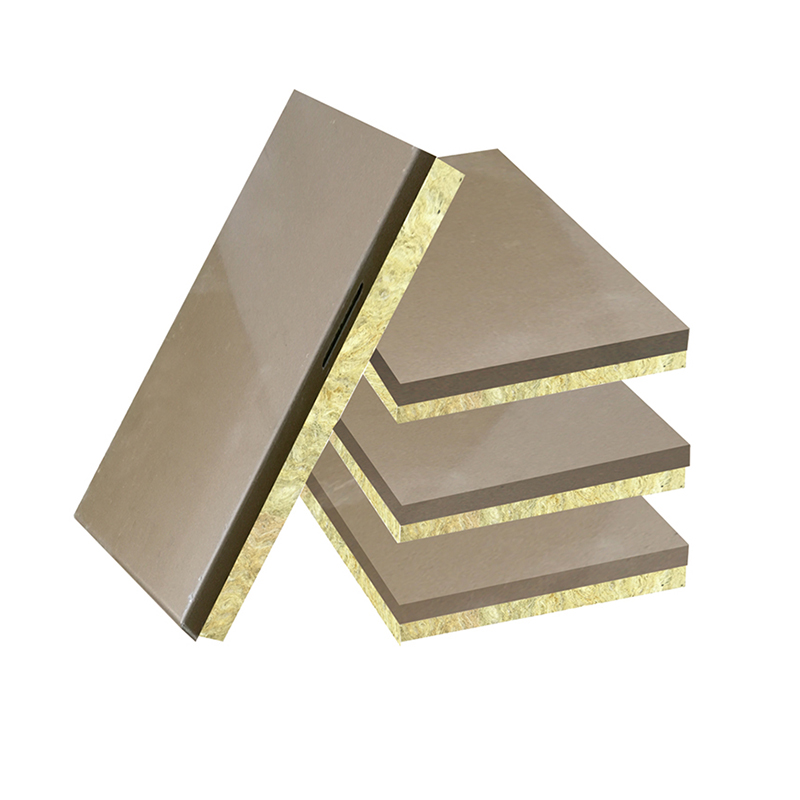

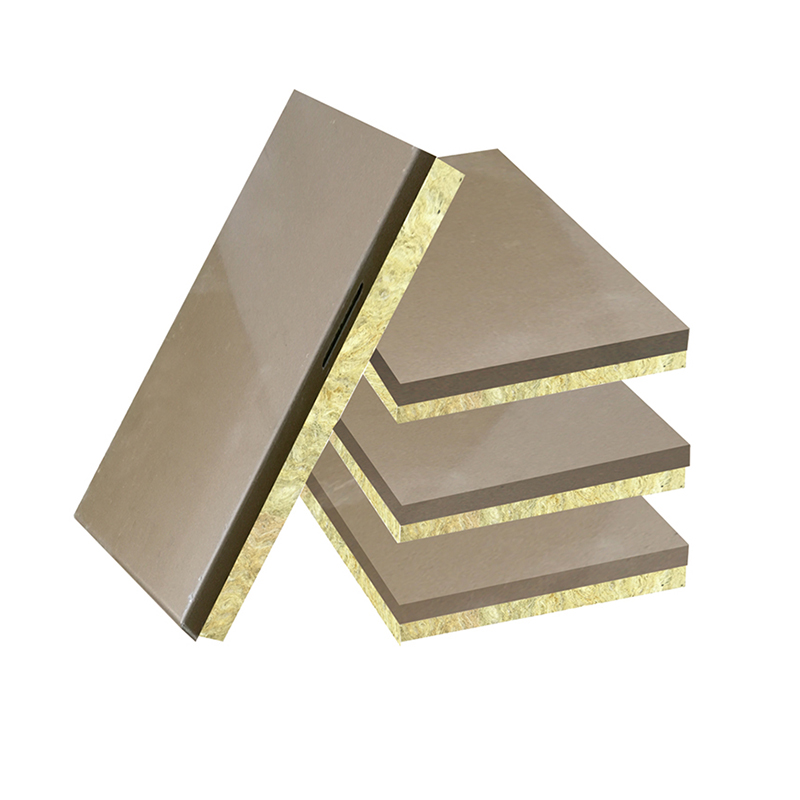

2025-09-08 The advantages of J-type rock wool insulation and decorative integrated board are as follows: excellent thermal insulation performance, low thermal conductivity: As the core insulation material, rock wool has a thermal conductivity of only 0.018~0.024W/(m·K), which is about 1/2 of traditional EPS materials, which can effectively reduce heat transfer and reduce heating and cooling energy consumption. The energy-saving effect is significant: when meeting the same insulation requirements, the thickness of the building's outer enclosure structure can be reduced and the indoor use area can be increased. Home use can reduce the air conditioner electricity bill by 30% to 50%, saving an average of 900 to 1,500 yuan per year. Excellent fire resistance Class A fireproof material: Rock wool itself has extremely high fire resistance, fire resistance level reaches A1, high temperature resistance above 1200℃, no toxic gases are produced during combustion, it complies with the requirements of the new national fire protection regulations and can effectively prevent the spread of fire. Safety guarantee: Applicable to buildings with strict fire prevention requirements, such as high-rise residential buildings, commercial centers, etc., providing reliable protection for the safety of personnel and property.

Read More

2025-09-05 Under normal use and maintenance conditions, the average lifespan of polyurethane hard foam insulation composite panels can reach more than 30 years, and some high-quality products can even reach 50 years. This conclusion is based on the following key factors: 1. Material characteristics and durability closed-cell structure: The porosity structure of polyurethane hard bubbles is stable, basically a closed-cell structure. This structure not only has excellent thermal insulation performance, but also has good freeze-thaw resistance and sound absorption. High closed cell rate can prevent air from flowing between the cells, reduce convection heat transfer, thereby improving thermal insulation performance and extending the service life of the material. Strong resistance to deformation: Polyurethane hard bubbles are not easy to crack, the finish is stable and safe, and can adapt to normal deformation of building structures without cracks, hollowing and other phenomena. Weather resistance and chemical stability: Polyurethane hard bubbles can be used for a long time in an environment of -50℃ to 150℃, and the short-term use temperature can even reach 250℃ without any damage. Its physical and chemical properties are very stable and insoluble in most solvents

Read More

2025-09-03 Polyurethane hard bubble insulation and decorative integrated board (referred to as 'polyurethane integrated board') is a new building material integrating thermal insulation, decoration, waterproofing and other functions, and is widely used in building exterior wall insulation and decoration projects. The following matters should be paid attention to during use to ensure construction quality and long-term performance: 1. Prepare environmental conditions before construction. Temperature requirements: The construction environment temperature should be between 5℃ and 35℃. Heating measures should be taken at low temperatures (<5℃). At high temperatures (>35℃), direct sunlight should be avoided to cause the adhesive to cure too quickly. Humidity control: The relative humidity should be ≤80%. Construction is prohibited in rainy, foggy or strong windy weather (wind speed > level 5) to prevent moisture from affecting the bonding strength. Base layer treatment: The base layer wall needs to be flat, dry, oil-filled, and floating ash, and the flatness deviation is ≤4mm/2m (check with a 2-meter ruler). The concrete base layer needs to be maintained for more than 28 days, and the masonry walls need to be plastered and leveled and dried (including

Read More

2025-08-27 Polyurethane hard bubble waterproof and insulation integrated board is a new type of building board that integrates waterproof, insulation, heat insulation, lightweight, durability and other functions. It is widely used in industrial factories, cold storage, civil buildings exterior walls, roofs and other scenarios. Its core advantage lies in combining the high performance of polyurethane hard foam with the convenient construction characteristics of the board. The following is a detailed introduction to the advantages: 1. Excellent thermal insulation performance Low thermal conductivity The thermal conductivity of polyurethane hard foam is only 0.022-0.028 W/(m·K), far lower than traditional insulation materials (such as polystyrene board 0.038 W/(m·K), rock wool 0.035 W/(m·K)), which can effectively reduce heat transfer and reduce building energy consumption. Application scenario: It is suitable for buildings with severe cold areas or high energy-saving requirements, such as northern residential exterior wall insulation, cold storage enclosure structure, etc. Closed cell structure, moisture-proof and heat-insulated polyurethane hard bubbles have a closed cell rate of up to 95%, making it difficult to penetrate moisture, avoiding water absorption

Read More

2025-08-25 Q-shaped rock wool insulation and decorative integrated board is a new building exterior wall material integrating thermal insulation, fire protection and decorative functions. It uses rock wool as the core insulation layer and is covered with metal or non-metal decorative panels. It is made of factory prefabricated to achieve integrated molding. Its application range is wide, covering multiple fields such as civil, commercial, industrial and municipal. The following analysis is carried out from the perspective of specific scenarios and advantages: 1. New residential buildings in the field of civil construction: suitable for exterior wall insulation and decoration systems such as high-rise apartments and villas, replacing the step-by-step construction of traditional insulation layer + decorative surface layer, shortening the construction period by 30%-50%. Renovation of old houses: Directly cover the original exterior walls to solve the problems of poor insulation performance and outdated appearance of old buildings, without the need to demolish the original structure and reduce the renovation cost. Typical case: residential projects in the centralized heating area in the north effectively reduce heat loss through rock wool insulation layer (thermal conductivity ≤0.040W/(m·K)), and combine decorative panels to achieve aesthetics and seclusion.

Read More

2025-08-22 Polyurethane hard bubble insulation composite board (PU hard bubble composite board) is a highly efficient and energy-saving building insulation material. It is composed of polyurethane hard bubble core material and metal or non-metal panels. It has the advantages of low thermal conductivity, strong wind pressure, and adjustable fire resistance. However, its use must strictly follow the specifications, otherwise it may cause insulation failure, safety hazards or shorten service life. The following are the key precautions and detailed descriptions: 1. Precautions for design stage fire protection performance matching standards: Select the fire protection level according to the 'Fire Protection Code for Building Design' (GB50016). For residential buildings with a building height of >54m or public buildings with a building height of >50m, the exterior wall insulation material must be Class A (not burnable). Other buildings can adopt B1 (flammable retardant) or B2 (flammable), but fireproof isolation belts are required. Non-standard scenarios: If the project requirements are higher than the national standards (such as data centers, chemical plants), PU hard foam core materials with flame retardant added (oxygen index ≥28%

Read More