1180 * 600 * 20 (thickness and above)

Thermal conductivity: ≤ 0.048W/(m · K)

Hydrophobic rate: ≥ 98.0%

Dimensional stability: ≤ 1.0%

Combustion performance: Class A

Excellent fire resistance performance;

Reliable quality, it is not easy to cause cracking of the board or large-scale detachment of the wall when applied in the external insulation plastering system;

Simple and convenient construction;

Integrated composite can eliminate the use of perforated inorganic backboards.

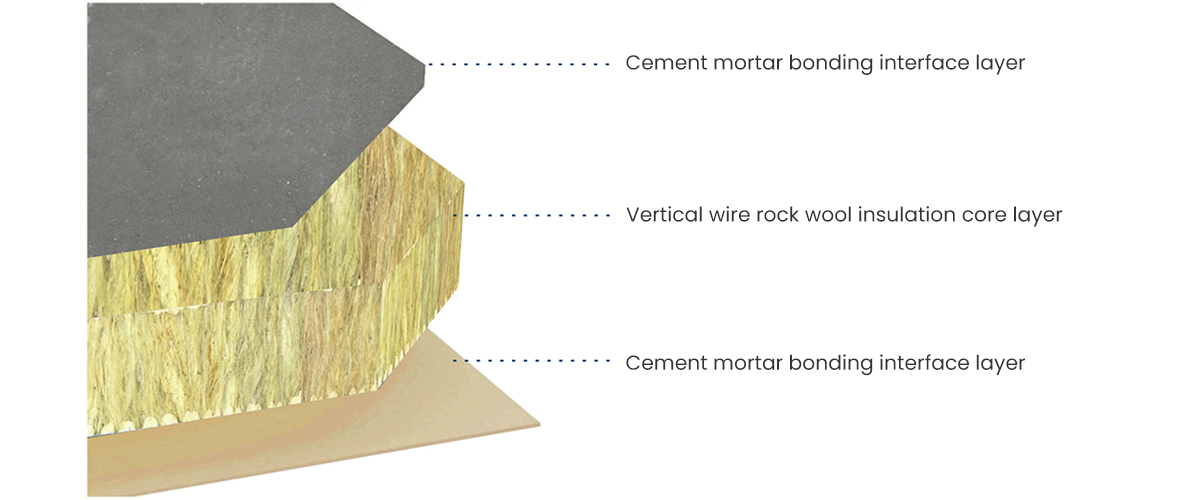

A new type of thermal insulation composite board with vertical silk wool as the core material, polyurethane foam adhesive as the bonding material, and double-sided composite cement mortar as the bonding interface layer.

By introducing the interface layer, the three major defects of the rock wool board on the wall can be changed:

1. Low tensile strength;

2. Low compressive strength;

3. Water absorption

The rate is too high. Traditional rock wool boards have low adhesion to walls and are prone to cracking and detachment; By improving the interface layer, it effectively prevents moisture from entering the rock wool body, greatly reducing its water absorption rate and enhancing its bonding strength and effectiveness; And the vertical rock wool strip can significantly improve the compressive and tensile properties of the insulation layer and the mechanical stability of the insulation system.

Suitable for building exterior wall external insulation systems and integrated external insulation decoration systems with high fire prevention requirements.

1180 * 600 * 20 (thickness and above)

Thermal conductivity: ≤ 0.048W/(m · K)

Hydrophobic rate: ≥ 98.0%

Dimensional stability: ≤ 1.0%

Combustion performance: Class A

Excellent fire resistance performance;

Reliable quality, it is not easy to cause cracking of the board or large-scale detachment of the wall when applied in the external insulation plastering system;

Simple and convenient construction;

Integrated composite can eliminate the use of perforated inorganic backboards.

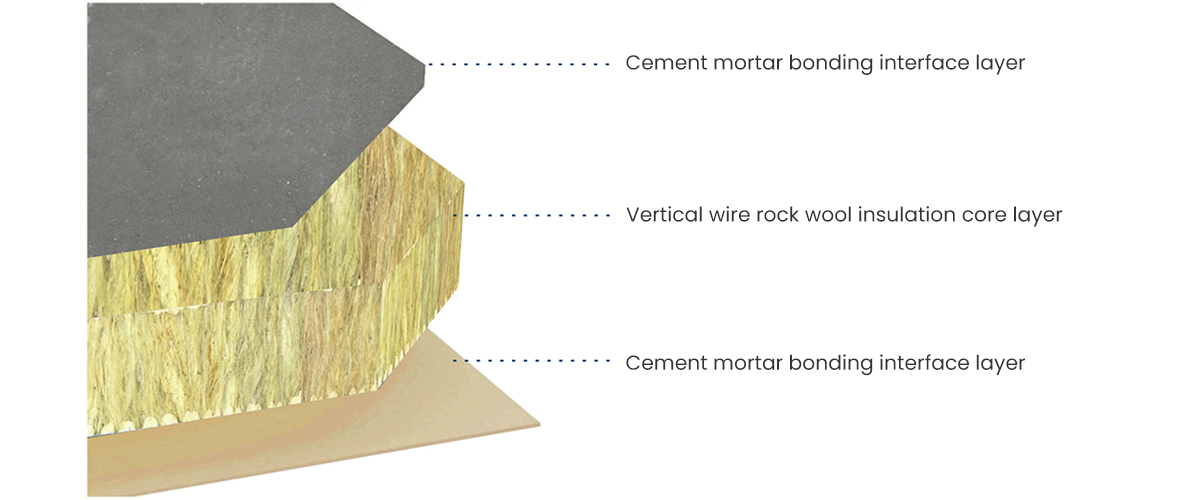

A new type of thermal insulation composite board with vertical silk wool as the core material, polyurethane foam adhesive as the bonding material, and double-sided composite cement mortar as the bonding interface layer.

By introducing the interface layer, the three major defects of the rock wool board on the wall can be changed:

1. Low tensile strength;

2. Low compressive strength;

3. Water absorption

The rate is too high. Traditional rock wool boards have low adhesion to walls and are prone to cracking and detachment; By improving the interface layer, it effectively prevents moisture from entering the rock wool body, greatly reducing its water absorption rate and enhancing its bonding strength and effectiveness; And the vertical rock wool strip can significantly improve the compressive and tensile properties of the insulation layer and the mechanical stability of the insulation system.

Suitable for building exterior wall external insulation systems and integrated external insulation decoration systems with high fire prevention requirements.