| Availability: | |

|---|---|

| Quantity: | |

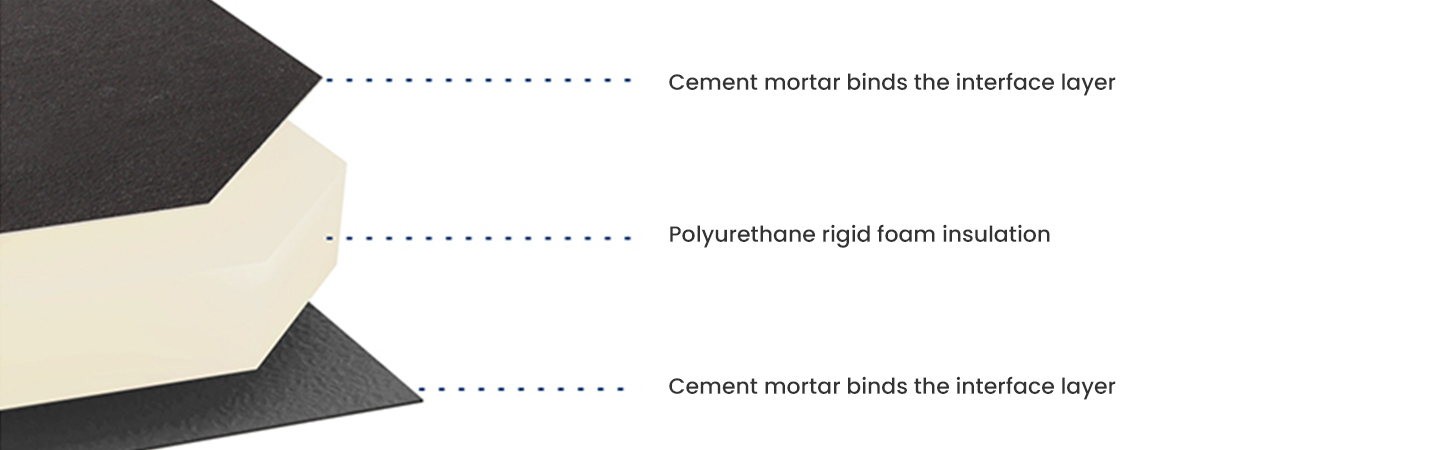

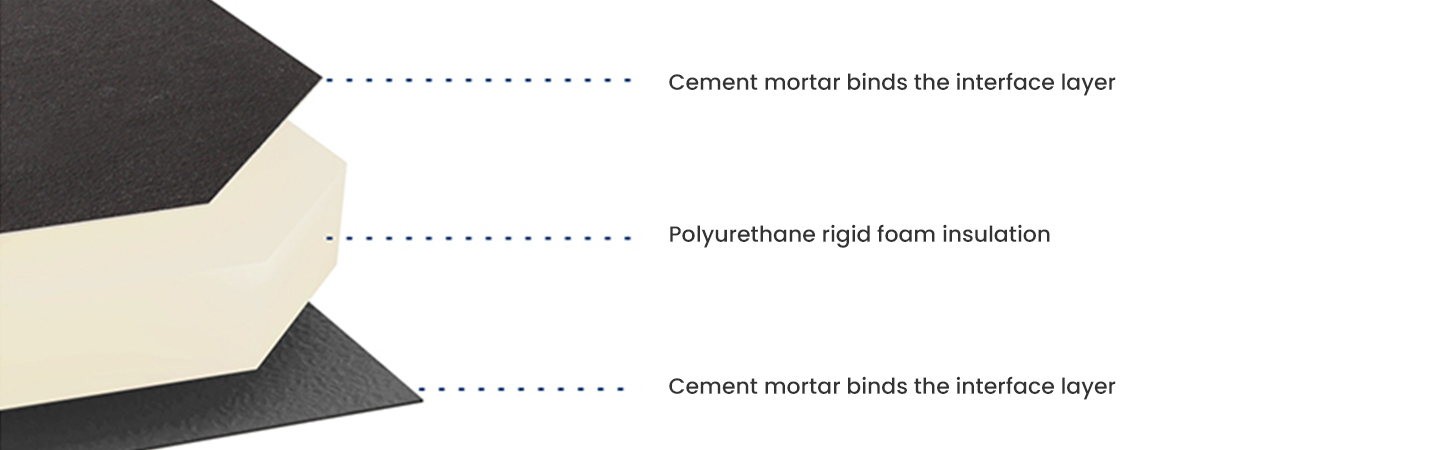

Product Construction

The factory specializes in the production line of polyurethane hard foam as the core material, and the double-sided composite cement mortar is the reinforced thermal insulation composite board with the interface layer.

Compound Purpose

The original organic foam is hydrophobic and the cement-based adhesive (plastering) slurry is difficult to bond, and it is easy to crack and fall off.

Various properties have been further strengthened and consolidated, which greatly increases the dimensional stability, compressive strength, tensile strength and aging resistance of the plate;

The possibility of contact between the surface of organic foam and the fire source becomes the possibility of contact between the surface of the inorganic non-combustible material and the fire source, which solves the fire hazard in the storage, transportation, construction and use of the product.

Exterior wall external thermal insulation coating or surface brick system;

Dry-hung stone curtain wall and metal curtain wall filling insulation;

Insulation of roof, floor, basement and interior wall.

Dimensions (mm)

Dimensions (mm)1200x600x10-80 (thickness)

Core density: >35kg/m

Thermal conductivity: ≤0.024w/m·k

Heat storage coefficient: 0.36W/m' K

The correction factor is 1.10

Compression: >150kPa

The tensile strength perpendicular to the surface direction > 100kPa

Core combustion performance: B2, B1 grade

Energy saving and high efficiency: extremely low thermal conductivity, the same thickness of insulation materials, the heat transfer coefficient value of the insulation system is smaller;

Fire safety: The technology of double-sided composite cement mortar bonding interface layer of thermosetting polyurethane rigid foam core layer is adopted, which completely avoids fire hazards in the process of product storage, installation and construction. After the thermal insulation system is formed, the combustion performance reaches the composite A level, which realizes the fire prevention of materials and the fire prevention of the system, and solves the fire prevention problem of external thermal insulation.

Reliable quality: good heat resistance, dimensional stability, tensile strength and excellent adhesion, which solves the engineering quality problems such as cracking of the insulation system, water seepage hollowing, and falling off;

Simple construction: factory, standardization, and construction standardization reduce the difficulty of insulation system construction and the influence of human factors, greatly improve the construction progress of the project, and solve the problem of on-site supervision.

Thermal insulation effect

The thermal insulation composite board has good thermal insulation performance, which ensures that the system uses the thinnest thermal insulation material when meeting the thermal insulation needs of the building, and provides a strong base guarantee for the requirements of high standard thermal insulation. At the same time, the nature of the insulation material

It can ensure the thermal balance of the building envelope to a large extent.

Reliable anti-cracking, anti-water seepage and anti-shedding protection

With a simple base treatment, it can be applied directly on any surface that meets the requirements for base flatness. Good dimensional stability and adhesion ensure the safety of the system, truly realize the product factory, technical standardization, and construction standardization, greatly reduce the pressure of project supervision, and provide users with the most reliable quality of energy-saving projects.

Unique fire safety

Thermosetting foam and double-sided inorganic mortar coating, so that the system will not ignite or spread in the event of fire during construction and use, and the system will reach Class A fire prevention.

A truly reassuring facing brick finishing system

The thermal insulation composite panel is up to 120 °C suitable for the environment, excellent dimensional stability (≤0.5%), better thermal insulation performance (≤ 0.024w/m·k), and because of the enhanced treatment of the interface layer of the thermal insulation composite panel, it provides strong structural tensile strength (>150kPa) for the system, which maximizes the shear bearing capacity of the system and the functions of anti-cracking, anti-water seepage and anti-shedding.

Reasonable cost, more cost-effective

The cost is slightly higher than that of the polystyrene board system, but it provides performance beyond the incomparable performance of the polystyrene board system, a wider range of applications, a safer system structure, and a longer service life.

Preparation of adhesive mortars |  Box point method |  Paste the board on the wall |

Install the anchors |  Plastering the bottom layer of plastering mortar, pasting the mesh cloth |  Plastering layer plastering mortar |

Product Construction

The factory specializes in the production line of polyurethane hard foam as the core material, and the double-sided composite cement mortar is the reinforced thermal insulation composite board with the interface layer.

Compound Purpose

The original organic foam is hydrophobic and the cement-based adhesive (plastering) slurry is difficult to bond, and it is easy to crack and fall off.

Various properties have been further strengthened and consolidated, which greatly increases the dimensional stability, compressive strength, tensile strength and aging resistance of the plate;

The possibility of contact between the surface of organic foam and the fire source becomes the possibility of contact between the surface of the inorganic non-combustible material and the fire source, which solves the fire hazard in the storage, transportation, construction and use of the product.

Exterior wall external thermal insulation coating or surface brick system;

Dry-hung stone curtain wall and metal curtain wall filling insulation;

Insulation of roof, floor, basement and interior wall.

Dimensions (mm)

Dimensions (mm)1200x600x10-80 (thickness)

Core density: >35kg/m

Thermal conductivity: ≤0.024w/m·k

Heat storage coefficient: 0.36W/m' K

The correction factor is 1.10

Compression: >150kPa

The tensile strength perpendicular to the surface direction > 100kPa

Core combustion performance: B2, B1 grade

Energy saving and high efficiency: extremely low thermal conductivity, the same thickness of insulation materials, the heat transfer coefficient value of the insulation system is smaller;

Fire safety: The technology of double-sided composite cement mortar bonding interface layer of thermosetting polyurethane rigid foam core layer is adopted, which completely avoids fire hazards in the process of product storage, installation and construction. After the thermal insulation system is formed, the combustion performance reaches the composite A level, which realizes the fire prevention of materials and the fire prevention of the system, and solves the fire prevention problem of external thermal insulation.

Reliable quality: good heat resistance, dimensional stability, tensile strength and excellent adhesion, which solves the engineering quality problems such as cracking of the insulation system, water seepage hollowing, and falling off;

Simple construction: factory, standardization, and construction standardization reduce the difficulty of insulation system construction and the influence of human factors, greatly improve the construction progress of the project, and solve the problem of on-site supervision.

Thermal insulation effect

The thermal insulation composite board has good thermal insulation performance, which ensures that the system uses the thinnest thermal insulation material when meeting the thermal insulation needs of the building, and provides a strong base guarantee for the requirements of high standard thermal insulation. At the same time, the nature of the insulation material

It can ensure the thermal balance of the building envelope to a large extent.

Reliable anti-cracking, anti-water seepage and anti-shedding protection

With a simple base treatment, it can be applied directly on any surface that meets the requirements for base flatness. Good dimensional stability and adhesion ensure the safety of the system, truly realize the product factory, technical standardization, and construction standardization, greatly reduce the pressure of project supervision, and provide users with the most reliable quality of energy-saving projects.

Unique fire safety

Thermosetting foam and double-sided inorganic mortar coating, so that the system will not ignite or spread in the event of fire during construction and use, and the system will reach Class A fire prevention.

A truly reassuring facing brick finishing system

The thermal insulation composite panel is up to 120 °C suitable for the environment, excellent dimensional stability (≤0.5%), better thermal insulation performance (≤ 0.024w/m·k), and because of the enhanced treatment of the interface layer of the thermal insulation composite panel, it provides strong structural tensile strength (>150kPa) for the system, which maximizes the shear bearing capacity of the system and the functions of anti-cracking, anti-water seepage and anti-shedding.

Reasonable cost, more cost-effective

The cost is slightly higher than that of the polystyrene board system, but it provides performance beyond the incomparable performance of the polystyrene board system, a wider range of applications, a safer system structure, and a longer service life.

Preparation of adhesive mortars |  Box point method |  Paste the board on the wall |

Install the anchors |  Plastering the bottom layer of plastering mortar, pasting the mesh cloth |  Plastering layer plastering mortar |